Your Complete Guide to Cut-Resistant Gloves

Safety gloves are essential for ensuring the protection of workers in industries such as construction, manufacturing and food processing. For those working with machinery, tools, and sharp objects or materials, cut-resistant gloves provide a more robust protective barrier, significantly reducing the risk of cuts and lacerations.

This guide will provide a detailed look at cut-resistant gloves to help you make informed decisions when purchasing gloves for your workers. By selecting the right gloves for specific tasks and ensuring a proper fit, employers can keep their workers well-protected and comfortable, minimize the risk of injuries in the workplace and maximize the safety benefits of cut-resistant gloves.

Understanding Glove Testing and Ratings

EN388

EN388 is the European standard for protective gloves. It uses a series of tests to evaluate glove performance, assigning ratings that help users select the appropriate gloves for their tasks. The ratings are displayed as a pictogram followed by four numbers and two letters, indicating the glove's performance against each hazard.

While EN388 is widely recognized and used in many parts of the world, ANSI/ISEA 105 is more commonly adopted in the U.S. due to its alignment with local industry practices and regulatory preferences. Both standards assess gloves for abrasion, cut, tear, puncture, and impact resistance, but they use different testing methods and rating systems.

ANSI/ISEA 105-2016

ANSI/ISEA 105-2016 applies strict testing methods to gloves to ensure workers are properly protected. This standard provides a consistent way to assess the cut, abrasion, and puncture resistance of gloves used in various industries, helping employers select the appropriate hand protection for specific hazards. These three ratings are communicated on the back of most SAFEGEAR gloves to provide, at a quick glance, the protective level of gloves in the workplace:

- Abrasion Resistance:

Gloves are evaluated for abrasion resistance by scraping the fabric repeatedly using abrasive weighted wheels. The number of revolutions need to wear through the coating and liner equates to an abrasion resistance score (0-6), with 6 representing the highest level of abrasion resistance. This test indicates how well gloves can withstand wear and tear.

- Cut Resistance:

The ANSI ASTM F2992-15 Cut Resistant Standard evaluates the cut resistance of gloves by moving a weighted straight razor across the glove fabric until enough weight is applied to cause the razor to cut the fabric. The amount of pressure (force) needed to cut the fabric determines the cut resistance level. In 2016, the testing methods were revised to provide better division between the levels. It now includes 9 levels instead of 5 (A1-A9), with A1 being the least cut-resistant and A9 being the most cut-resistant.

- Puncture Resistance:

A puncture resistance test measures the amount of force required to pierce through a material using a standardized blunt stylus. This assesses the glove's ability to resist punctures from objects like needles or nails. The measured force is converted to a rating scale of 1-5, with 5 being the highest level of puncture resistance.

Applying Cut Levels A1-A9

Choosing the right cut-resistant gloves for your workers involves a balance between level of protection and ability to perform required tasks efficiently and comfortably.

Level A1 is rated for light cut hazards like material handling, packaging or small parts assembly with cut force resistance of 200-499 grams.

- Cut Force: 200-499

- Hazard: Nuisance/Minimal Cut Hazards

- Tasks: Material Handling, Knives/Scissors/Blades, Cardboard

Level A2 offers protection from light/medium cut hazards that include the job tasks under A1 with increased cut force resistance of 500-999 grams.

- Cut Force: 500-999

- Hazard: Low Cut Hazards

- Tasks: Material Handling, Knives/Scissors/Blades, Cardboard

Level A3 offers protection from light/medium cut hazards that include the job tasks under A1 and A2, including handling raw materials, general manufacturing, and construction activities but with increased cut resistance of 1,000-1,499 grams.

- Cut Force: 1,000-1,499

- Hazard: Low Cut Hazards

- Tasks: Material Handling, Knives/Scissors/Blades, Glass, Cardboard

Level A4 is rated for light/medium cut hazards like drywalling, metal fabrication, and metal handling with cut resistance of 1,500-2,199 grams.

- Cut Force: 1,500-2,199

- Hazard: Moderate Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Knives/Scissors/Blades, Glass, Cardboard

Level A5 rating protects workers' hands from medium cut hazards during food prep/processing, HVAC work, appliance manufacturing, and automotive assembly with cut resistance of 2,200-2,999 grams.

- Cut Force: 2,200-2,999

- Hazard: High Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Automotive, HVAC, Appliance Manufacturing, Knives/Scissors/Blades, Glass, Cardboard, Raw Materials

Level A6 offers increased protection from high cut hazards like glass manufacturing, changing blades, and window manufacturing with cut resistance of 3,000-3,999 grams.

- Cut Force: 3,000-3,999

- Hazard: High Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Automotive, HVAC, Appliance Manufacturing, Construction Work, Stamping, Knives/Scissors/Blades, Glass, Cardboard, Raw Materials

Level A7 offers protection from high cut hazards like metal stamping, glass manufacturing, changing slitter blades and window manufacturing with cut force resistance of 4,000-4,999 grams.

- Cut Force: 4,000-3,999

- Hazard: Extreme Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Automotive, HVAC, Appliance Manufacturing, Construction Work, Stamping, Knives/Scissors/Blades, Glass, Cardboard, Raw Materials

Level A8 provides maximum cut resistance of 5,000-5,999 grams for high hazards while handling slitter blades, metal stamping, glass manufacturing, and window manufacturing.

- Cut Force: 5,000-5,999

- Hazard: Extreme Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Automotive, HVAC, Appliance Manufacturing, Construction Work, Stamping, Knives/Scissors/Blades, Glass, Cardboard, Raw Materials

Level A9 provides extreme cut protection while handling slitter blades, metal stamping, glass manufacturing, and window manufacturing, providing at least 6,000 grams of cut resistance.

- Cut Force: 6,000+

- Hazard: Extreme Cut Hazards

- Tasks: Material Handling, Metal Fabrication, Automotive, HVAC, Appliance Manufacturing, Construction Work, Stamping, Knives/Scissors/Blades, Glass, Cardboard, Raw Materials

Cut Protection Starts With Cutting-Edge Materials

Cut-resistant gloves have two components: base materials and coating. Because each combination of materials and coating has pros and cons, the best glove choice depends on the specific requirements of the task.

Cut-Resistant Materials

BLADESTOP

- Manufacturer-patented Bladestop offers a high-performance protective material that combines a graphene technology-based engineered fiber with other common fibers like HPPE and recycled polyester to form the most robust glove material available

- Incredibly lightweight and breathable, offers cool touch comfort

- Enhanced grip, along with chemical, cut, abrasion and puncture resistance

- Lint free and soft for all-day comfort

- Many Bladestop glove combinations are free of metal and glass fiber, eliminating skin irritation

- Bladestop combined with steel or tungsten provides even stronger hand protection for tasks involving high-cut hazards

HPPE/STEEL FIBER + Various Combinations of Polyester, Spandex, Nylon, Cotton, Tungsten

- HPPE and steel fiber, blended with various combinations of polyester, spandex, nylon and cotton, provide a high cut-resistant glove material that is tough without compromising dexterity

- Durable, capable of heavy use in harsh conditions

- Adding polyester and/or cotton wicks moisture away from the skin to keep hands dry and comfortable; reduces friction and hand irritation for all-day comfort

- Adding spandex and/or nylon ensures a snug and comfortable fit that adapts to the shape of a worker's hands to prevent fatigue

- Incorporating tungsten adds heat and chemical corrosion resistance

HPPE/FIBERGLASS

- High-performance polyethylene and fiberglass gloves are known for exceptional cut resistance and durability, making them ideal for handing sharp objects

- Lightweight and comfortable, allows extended use without causing fatigue

- Offers good flexibility and dexterity

POLYESTER

- Known for its strength and resistance to stretching, shrinking, and wrinkles, resulting in gloves that are durable and able to withstand heavy use

- Repels water and other liquids, and is naturally resistant to many common chemicals and solvents, keeping hands dry and protected in wet or oily environments

- Provides a snug and comfortable fit that results in excellent dexterity and grip

- Easy to clean and dry quickly

SPANDEX + Various Combinations of Polyester, Nylon, Fiberglass and Copper

- Excellent stretch and flexibility, ensures a snug, comfortable fit that adapts to the shape of a worker's hands

- Polyester is lightweight and adds durability, extending the life of the glove, along with moisture-wicking capabilities to keep the hands dry

- Nylon is known for its strength and abrasion resistance, making these gloves durable and able to withstand regular use

- Fiberglass adds increased cut resistance

- Copper has antimicrobial properties to help reduce odor and growth of bacteria and fungi on the glove, keeping them fresh for longer periods; copper-infused gloves can help improve blood circulation to help reduce hand fatigue and discomfort

NYLON OUTER LAYER/ACRYLIC FLEECE LINER

- Known for its strength and abrasion resistance, nylon gloves are durable and able to withstand regular use

- Excellent stretching, ensures a snug fit

- Low lint, quick-drying, and resistant to water, chemicals, oils and solvents

- Acrylic fleece liner is made of synthetic fibers that create air pockets and provides a barrier against cold temperatures, resulting in insulation that traps body heat

- Gloves with fleece lining are the most common lightweight choice for cold conditions since they conserve body heat without adding bulk or weight

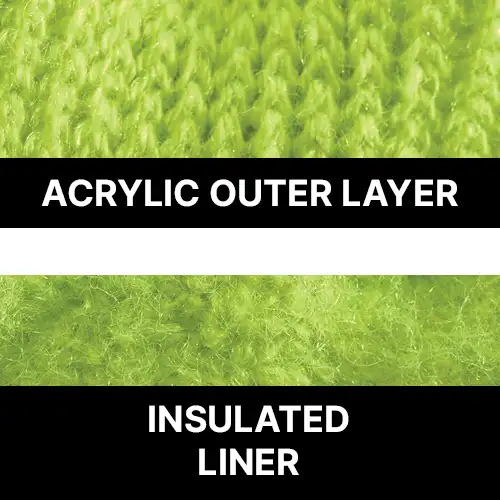

ACRYLIC OUTER LAYER/INSULATED LINER

- Known for its insulation properties, acrylic gloves are ideal for cold environments while still providing cut protection

- Soft, flexible and lightweight, ensures a comfortable fit for extended wear

- Durable for regular use in demanding environments

- Insulated liner is soft and warm, adding insulation and moisture-wicking capabilities

Glove Coatings

Glove coatings add a surface layer designed to enhance hand protection and worker safety in different ways:

- Strengthen grip

- Increase cut resistance

- Improve abrasion resistance

- Provide chemical resistance

- Maintain water repellence

- Boost protection from extreme temps

- Enhance dexterity and comfort

- Add puncture resistance

Latex

Natural rubber latex coating is durable, tough and flexible. It offers resistance to snags, punctures, abrasion, water and protein-based oils, resulting in superior grip, especially in dry conditions.

Foam latex glove coating is formed when latex is whipped or aerated to create a foam-like texture. This process results in a coating that is more breathable and comfortable compared to standard latex coatings.

Common Uses:

- Construction/Demolition

- Landscaping and Yard Work

- Manufacturing

- Material Handling

- Parts Handling

- Refrigerated Areas

- Warehousing

Crinkle latex glove coating is made when a texture is added to the surface of the latex to create a crinkled or wrinkled surface. This texture channels fluids away from the surface for better contact and control.

Common Uses:

- Commercial Fishing/Fisheries

- Construction/Demolition

- Landscaping and Yard Work

- Manufacturing

- Parts Handling

- Refrigerated Areas

- Transport

Sandy latex glove coating includes a gritty texture over the latex coating with numerous small pockets that work like suction cups to push fluids away upon contact, providing a stronger grip. A second coating layer provides a thicker, more uniform layer, enhancing durability and barrier protection.

Common Uses:

- Commercial Fishing/Fisheries

- Construction/Demolition

- Machining Operations

- Manufacturing

- Masonry

- Material Handling

- Oil and Gas Industry

- Plumbing

- Refrigerated Areas

- Transport

Molded TPR

Thermoplastic rubber (TPR) is a thermoplastic rubber used to coat gloves in order to protect the hands and fingers from impact and reduce hand fatigue. Its elasticity helps disperse impact energy away from the bones.

Common Uses:

- Automotive

- Construction/Demolition

- Machining Operations

- Manufacturing

- Masonry

- Mining

- Oil and Gas Industry

- Offshoring

- Plumbing

- Transport

- Utilities

Flat Polyurethane

Polyurethane (PU) glove coating (a type of plastic) is made of a string, durable, flexible polymer that provides a smooth, non-slip glove surface. Gloves with this coating offer flexibility, dexterity and tactile sensitivity. They’re popular in many industries due to their versatility and low cost.

Common Uses:

- Automotive

- Janitorial

- Landscaping and Yard Work

- Maintenance

- Manufacturing

- Material Handling

- Parts Handling

- Plumbing

Nitrile

Nitrile is made of a synthetic rubber compound that offers excellent resistance to tears, abrasions and punctures, and provides a barrier against a wide range of chemicals. Nitrile coated gloves also offer flexibility, dexterity, and durability, along with comfort and reduced hand fatigue. Because nitrile is latex-free, it is also a good choice for those with latex allergies. Gloves with nitrile coating are commonly used in industrial settings where workers handle oily parts or need grip in wet or dry conditions.

Flat/smooth nitrile produces a shiny, smooth appearance because there is no air blown into the material during manufacturing. The smooth surface will not absorb liquids into the coating, therefore hands are kept dry and clean. Gloves can have a single layer or double layer for increased durability and protection.

Common Uses:

- Automotive

- Construction/Demolition

- Janitorial

- Maintenance

- Manufacturing

- Material Handling

- Parts Handling

- Refrigerated Areas

Micro-foam nitrile coating is made of thousands of micro bubbles that increase the glove’s surface area. This allows the coating to absorb oils away from the object in order to maintain excellent grip in oily conditions. Micro-foam is thinner than regular foam, providing better breathability and dexterity.

Common Uses:

- Automotive

- Commercial Fishing/Fisheries

- Construction/Demolition

- Janitorial

- Manufacturing

- Material Handling

- Oil and Gas Industry

- Offshoring

- Plumbing

- Transport

- Utilities

- Warehousing

Sandy nitrile glove coating includes a gritty texture that increases friction for enhanced grip while numerous small pockets work like suction cups to push fluids away upon contact.

Common Uses:

- Commercial Fishing/Fisheries

- Construction/Demolition

- Janitorial

- Machining Operations

- Manufacturing

- Masonry

- Material Handling

- Oil and Gas Industry

- Offshoring

- Plumbing

- Transport

Nitrile dots are tiny raised textured bumps added to the surface of the nitrile coating, designed to increase friction and provide superior grip when working with slippery surfaces or wet objects. They are often included in micro-foam nitrile coating for even better grip and breathability.

Common Uses:

- Automotive

- Commercial Fishing/Fisheries

- Construction/Demolition

- Janitorial

- Maintenance

- Manufacturing

- Transport

6 Common Myths About Cut-Resistant Gloves

Myth 1: Cut-resistant are cut-proof

Fact: Cut-resistant gloves are designed to resist cuts, but they are not 100% cut proof. Cut resistant means they are built to withstand a certain amount of force (resulting in a cut level A1-A9 designation), needed to provide a barrier that reduces the risk of injury.

Myth 2: Higher cut resistance levels are always better

Fact: As the cut protection increases, dexterity, tactile sensitivity and comfort can decrease because the glove material is sometimes made of thicker or more rigid materials. Higher cut resistance gloves can also be more expensive, making them less cost effective for tasks involving low cut hazards. Finding the best balance of cut level, dexterity, comfort, grip and cost helps ensure workers are protected and able to perform their tasks efficiently.

Myth 3: The entire glove is rated for cut level protection

Fact: Glove cut levels apply to the material used in the palm and fingers, which are most likely to come in contact with cut hazards. While some gloves are fully coated, most are only coated on the palm side. Therefore, the back of the hand is protected against cuts, but not always at the same level as the palm side. It’s important to check the cut level and construction details to ensure they provide protection for their intended use.

Myth 4: Any size will do

Fact: Cut-resistant gloves, especially, are designed to perform and protect best when it fits the worker. Gloves that are too loose can slip or get caught, while gloves that are tight can restrict movement and reduce dexterity.

Myth 5: All cut-resistant gloves are the same

Fact: Cut-resistant gloves are available in a variety of materials and coatings, providing different features to enhance functionality. Choosing the right glove for the task is critical to optimize comfort, protection, and performance.

Myth 6: Cut resistance decreases after washing

Fact: It’s a common myth that cut resistance decreases after washing. Quality cut-resistant gloves are designed to maintain their protective properties as long as the manufacturer’s care instructions are followed (avoid bleach and fabric softener, for instance). The material may become more relaxed and less stiff, but this doesn’t mean they lose their cut resistance. Cleaning gloves also removes dirt, oils and contaminants, which can help maintain the gloves’ effectiveness and hygiene.

How to care for cut-resistant gloves?

Proper cleaning, maintenance and storage of cut-resistant gloves are crucial for ensuring their effectiveness and longevity. Regular cleaning removes dirt, oils and other contaminants that can degrade the glove material and compromise its protective qualities. Maintenance, such as inspecting for tears and wear, ensures that the gloves remain in good condition and continue to provide the necessary protection against cuts and abrasions. Proper storage, away from direct sunlight and chemicals, prevents material degradation and maintains the gloves' integrity. Below are specific care instructions for leather, string, and dipped/coated gloves.

| Leather Work Gloves | String Gloves | Dipped Nitrile & PU Gloves | |

|---|---|---|---|

| Cleaning |

|

|

|

| Conditioning |

| n/a | n/a |

| Drying |

|

| |

| Storage |

|

|

|

| Do's & Don'ts |

|

|

|

When should I replace cut-resistant gloves?

It's important to replace cut-resistant gloves when they show signs of damage, reduced cut resistance, significant wear and tear (holes, fraying or thinning material), loss of grip (coating has worn down) reduced dexterity (gloves have become stiff or lose their flexibility), or unpleasant odor (buildup of bacteria and other contaminants). Regular inspection of gloves can help ensure gloves maintain optimal protection and performance.

Choosing The Right Cut-Resistant Glove

Choosing cut-resistant gloves involves several key considerations:

- Assess your workplace and identify cut hazards, such as sharp objects, glass, or metal edges

- Understand ANSI/ISEA 105-2016 cut levels

- Consider additional hazards, such as abrasion, puncture, and chemical exposure

- Select the right material

- Select the right coating

- Check fit and comfort

- Evaluate durability of gloves vs. task

- Test and verify gloves are appropriate for task

- Consider cost vs. budget

By following these steps, you can select the right cut-resistant gloves that provide optimal protection, comfort, and durability for your specific needs.

Why Choose SAFEGEAR gloves?

J. J. Keller is dedicated to providing the highest level of safety and comfort for workers through our proprietary line of SAFEGEAR® hand protection. Our mission is to create gloves that empower workers to perform their best while staying safe. We prioritize user fit and comfort, ensuring our gloves fit perfectly and allow for natural hand movement. SAFEGEAR® gloves also reflect our commitment to innovation and quality.

Shop our selection of cut-resistant gloves