CMV failure due to improper or inadequate maintenance. Data includes:

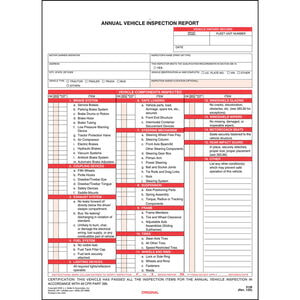

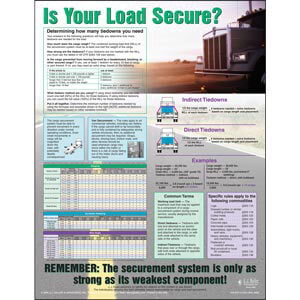

- Roadside violations for brakes, lights, other mechanical defects, or cargo securement;

- Crash reports citing a mechanical failure or inadequate cargo securement as a contributing factor; or

- Violations from an off-site investigation or an on-site investigation associated with pre-trip inspections, maintenance records, and repair records